Introduction:

Airflow charcoal making machine, which adopts advanced hot flue

carbonizing technology, is one of our latest developed products.

Modern-designed airflow charcoal making machine greatly increases

carbonizing ratio from about 88% to 99%, and shortens carbonizing

time (from 24 to 6 hours). Also this airflow charcoal making

machine is characterized by easy operation, safety, efficiency,

energy saving and environment protection.Inner pots of airflow

charcoal making machine for charcoal production can be hanged

outside, which will save a lot of cooling time, so the productivity

increases greatly. It is the ideal choice for charcoal production

plant.

The new environmentally friendly horizontal airflow carbonization

furnace adds a flue gas recovery device on the basis of the

original carbonization furnace. After the flue gas is recovered, it

can be dust-free and smoke-free. The recovered flue gas can be

ignited like liquefied gas for heating, cooking, and Dryer use. At

present, there are three types of carbonization furnaces, common

type (can only be used to produce charcoal, not to collect gas);

wood carbonization equipment (used to carbonize branches, wood

blocks, coconut shell blocks, scrap pieces in furniture factories,

etc.) This equipment can be configured The gas recovered by the

gasification furnace device can be turned into fuel gas for the

carbonization furnace's own use or other); the new horizontal

environmentally friendly carbonization furnace has the effect of

one machine and two purposes, and the materials can also be

directly carbonized, or can be carbonized after rods.

| model | 120 | 170a | 170b | 190 |

| capacity | 2T/24h | 4T/24h | 7T/24h | 10T/24h |

| dimension | 2.86*1.6*2.1m | 2.85*2.1*2.1m | 4.60*2.1*2.1m | 5.5*2.2*2.2m |

| weight | 1.68T | 3T | 3.5T | 6.8T |

| inner pot diameter | 1.2m | 1.7m | 1.7m | 1.9m |

| inner pot length | 2.6m | 2.2m | 4.4m | 5.3m

|

The main features of the new horizontal jet carbonization furnace:

①Continuity of production

②Good sealing performance

③The water cooling replaces the traditional natural cooling.

④Composite materials with high heat transfer and wear resistance

form a highly efficient carbonization chamber

⑤All gas is returned to the furnace for combustion without waste

gas pollution

Raw Materials:

Sawdust, Crops Straw(corn stalk, beanstalk, broomcorn stalk, cotton

stalk, rape stalk,palm kernel shell, groundnut stem, sunflower

stalk), Husk, Grass, Bush branches, Bamboo butt, Bamboo scraps,

Bagasse and so on.

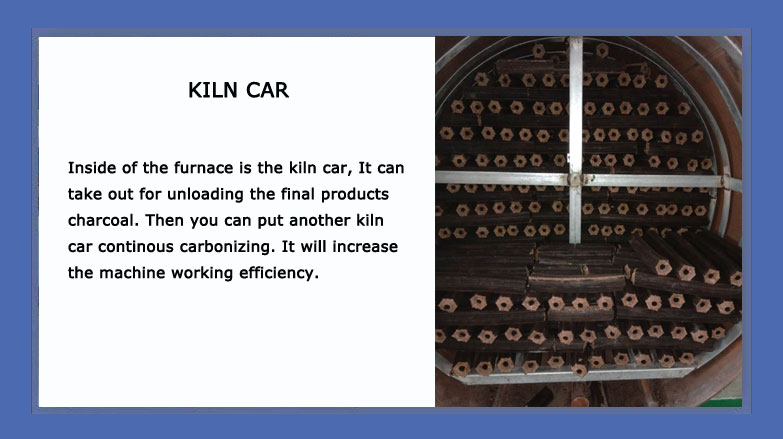

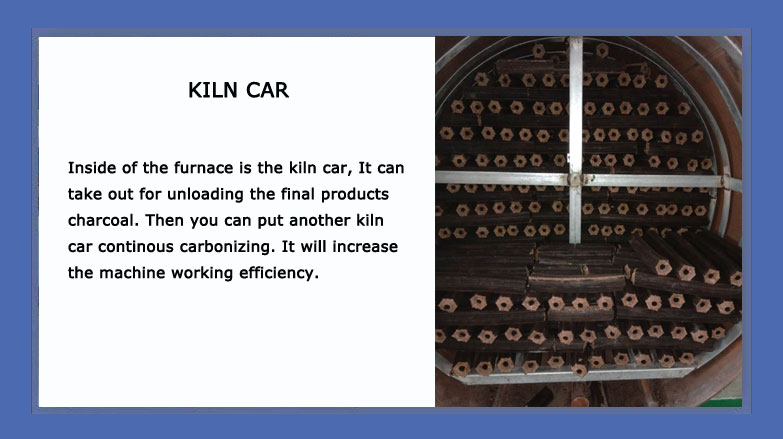

Carbonization stove:

The carbonization stove is a new designed machine for chargin the

wood briquette, bamboo, wood log, coconut shell and so on into

charcoal. It is selling well for its easy operating, high capacity,

good quality. Once carbonization need 8 hours, smokeless and the

raw materials can be wood log or other flammable goods.

The whole line of making wood briquette charcoal

1.Crush the raw material into small pieces (diameter is about

3-5mm);

2.Dry the material by machine or dried it in the sun , till the

moisture is less than 12%;

3.Put the material into feed let of briquette machine;

4.Produce the briquette stick from biomass material without any

additive;

5.Carbonized the briquette stick.

,

,