Introduction of High Production Capacity Biomass Charcoal

Briquetting Equipment Biomass Wastes To Fuel Biomass Charcoal

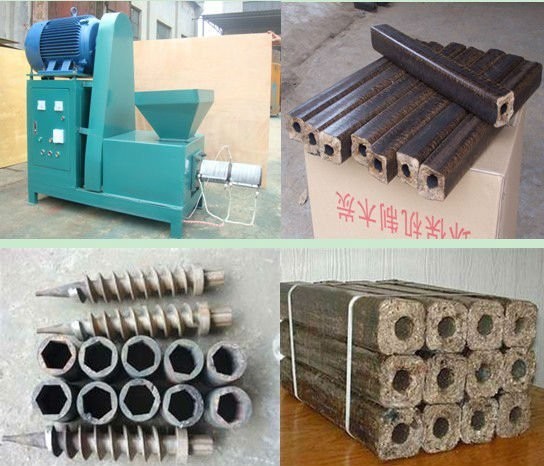

Briquette Machine

The biomass briquettes extruder machine is used to make briquettes

in charcoal, medicine, food, industry processing area. The biomass

briquette extruder making machine is use sawdust, crop straw, wood

branches, coconut shell, cotton stalks, sesame straw, sugarcane

waste, rice hulls, peanut shells, bamboo crumbs and other

agricultural wastes to make fuel briquette under high temperature

and pressure. This machine adopts high temperature indicator, it

can operate steady under setting temperature. It has the features

of reasonable structure, simple operature and maintenance, etc. The

solid fuel made by this machine can be burn very easily.

Advantage of High Production Capacity Biomass Charcoal Briquetting

Equipment Biomass Wastes To Fuel Biomass Charcoal Briquette Machine

1.Reasonable design, reliable quality, simple structure, convenient

operation, small size, small occupation area, labor saving and

electricity saving.

2. Auto-control electric heating device.

3. Use special wear-resistant material.

4. Suitable for all kinds of raw materials of biomass briquetting.

5. Improve the bearings to be more stable and durable.

6. Improve the structure of the molding cylinder.

7. Briquette machine can be 15kw/18.5kw/22kw-3phase-380v-50hz or

customer made.

Raw material request of High Production Capacity Biomass Charcoal

Briquetting Equipment Biomass Wastes To Fuel Biomass Charcoal

Briquette Machine

These raw materials are crushed first, and then compressed into

formed fuel products with high density and high calorific through

machine pressing and heating. Under high pressure to make it into

square and hollow rod solid charcoal fuel(mechanism charcoal).

Working with the principle of high pressure and high temperature,

no binder added to the raw material, so when burning there is no

pollution to the environment.

After carbonized briquettes features:

Long burning time: 5-7 hours

High calorific value: 8800Kcal

Low ash content: Below 2.6

The volatile matter should not be more than 9.5%

The fixed carbon shall not be less than 83.9%

Moisture content shall be not more than 4.0%

Smooth surface: without crackle

Environmental-friendly: without any chemical